Temporary power planning succeeds or fails on flexibility and protection, and selecting a Portable Distribution Box early helps teams manage changing loads, site movement, and safety compliance without costly rewiring; when deployment conditions evolve, a thoughtfully specified Portable Distribution Box positioned at the center of operations keeps connections organized, protected, and easy to audit. This guide explores how to evaluate environments, size loads, install correctly, and maintain mobile distribution so projects stay on schedule and within budget.

Understanding Use Cases for Mobile Power

Portable power is used wherever fixed infrastructure is impractical or unavailable. Construction sites, outdoor events, shipyards, maintenance shutdowns, and emergency response all rely on equipment that can be deployed quickly and relocated often. These scenarios demand rugged housings, clear labeling, and fast access for technicians. Mobility also introduces risk: frequent handling, transport vibration, and repeated connections can accelerate wear. Selecting equipment designed for these realities reduces downtime and improves safety outcomes.

Electrical Capacity, Protection, and Selectivity

Accurate load planning is the foundation of reliable temporary distribution. Identify continuous current, expected inrush from motors or lighting rigs, and diversity factors as equipment cycles on and off. Protection devices should be coordinated so downstream faults clear locally without tripping upstream supplies. Clear separation of circuits for lighting, tools, and sensitive electronics improves selectivity and simplifies troubleshooting. Oversizing modestly can reduce heat buildup and extend component life in high-duty cycles.

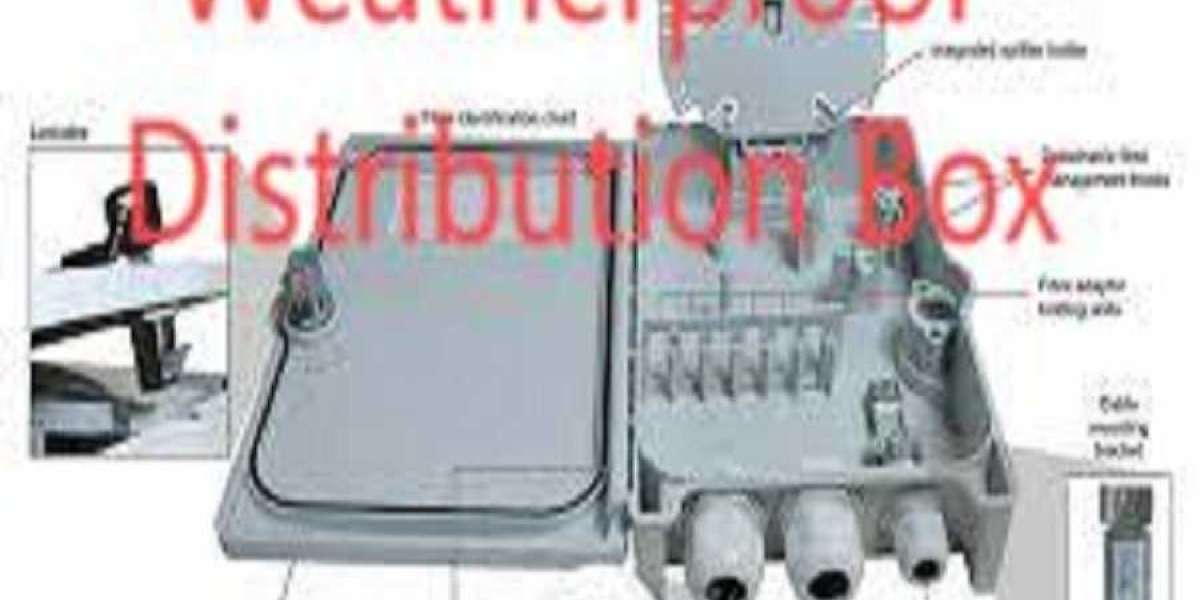

Enclosure Design, Materials, and Environmental Sealing

Mobility doesn’t excuse exposure. Rain, dust, mud, and accidental impacts are common on temporary sites. Impact-resistant polymers and corrosion-protected metals are popular choices, each offering trade-offs in weight and durability. Gaskets must retain elasticity after repeated opening, and latches should remain secure despite vibration. Evaluate ingress ratings against realistic exposure—pressure washing, wind-driven rain, or dusty conditions require more than basic sealing. Rounded edges, recessed handles, and protected connectors reduce damage during transport.

Nante Mobile Power Deployment Considerations

When standardizing fleets, consistency pays dividends. Look for product families with shared accessories, interchangeable modules, and clearly documented ratings so crews can deploy equipment confidently across sites. Removable gland plates, standardized outlets, and modular interiors simplify configuration changes. Clear instructions for transport, stacking, and securing during transit help preserve seals and connectors between deployments. Choosing a well-supported range reduces spare-part variety and shortens training time for technicians.

Installation, Placement, and Site Safety

Even temporary setups deserve disciplined installation. Place units on stable, elevated surfaces to avoid standing water and mechanical damage. Route cables to minimize trip hazards and protect them from sharp edges or vehicle traffic; use ramps or cable guards where necessary. Verify earthing continuity at each deployment and confirm protective devices are set correctly. Visible labeling and color coding help prevent misconnection during fast-paced operations, especially when multiple teams share power sources.

Commissioning Checks and Operational Readiness

Before energizing, perform a brief commissioning routine: visual inspection of housings and seals, torque checks on terminals, continuity verification, and functional testing of protective devices. Document baseline readings so changes over time are easy to spot. For events or critical works, keep a simple checklist posted inside the lid to standardize setup and teardown across crews and shifts.

Maintenance Between Deployments

Portable equipment benefits from between-job care. Clean housings, inspect connectors for discoloration or wear, and replace seals showing compression set. Check fasteners and handles for loosening after transport. Store units in dry conditions and cap unused outlets to keep contaminants out. A small maintenance kit—spare gaskets, fasteners, and labels—can return units to service quickly and prevent minor issues from compounding.

Planning for Lifecycle Cost and Scalability

Total cost of ownership includes more than purchase price. Consider transport damage, repair frequency, setup time, and the operational cost of outages. Modular designs that adapt to different site sizes reduce the need to own multiple specialized units. Standardization across projects simplifies inventory and speeds response when capacity must be added on short notice. Investing in durability and serviceability often lowers costs over the equipment’s working life.

Portable power distribution is a balance of speed, safety, and resilience. By defining use cases, sizing loads carefully, choosing robust materials, and enforcing disciplined installation and maintenance practices, teams achieve dependable temporary power that adapts to change. For available configurations, accessories, and deployment options to support mobile applications, visit https://www.nante.com/product/