Robots are no longer just for automotive factories; they are taking over the docks. The Digital Shipyard Market is witnessing a surge in robotic automation. From welding huge steel plates to painting hulls, machines are doing the heavy lifting. This shift reduces human risk and significantly speeds up production times. It marks a pivotal moment in maritime history.

Introduction

Shipbuilding is physically demanding and often dangerous work. It involves handling heavy materials in harsh environments. To address these challenges, the industry is embracing shipyard automation solutions. Robotics and Artificial Intelligence (AI) are at the forefront of this change.

The digital shipyard market is not just about software; it is about hardware that thinks. AI-powered ship design algorithms create optimal structures. Then, robots execute these designs with microscopic precision. This synergy between digital intelligence and physical action creates a highly efficient production loop.

Market Growth Factors/Drivers

A major driver for robotics is the shortage of skilled welders and laborers. The younger workforce is less inclined to take on manual labor jobs. Therefore, shipyards must automate to fill this gap. Robots can work tirelessly without breaks, increasing throughput.

Quality consistency is another factor. Human welders can get tired, leading to inconsistencies. Robots deliver the same high-quality weld every single time. This reduces the need for rework and inspections.

- Safety Improvements: Robots handle toxic paints and work in confined spaces.

- Speed: Automated cutting and assembly are significantly faster than manual methods.

- Cost Reduction: Long-term savings on labor and rework justify the initial investment.

Additionally, Maritime Industry 4.0 promotes the use of smart machines. These machines communicate with the central system, updating progress in real-time.

Segmentation Analysis

The robotics segment of the market can be broken down by task and type.

By Application

- Welding and Cutting: The most common use of robotics in shipyards.

- Painting and Blasting: Robots ensure even coats and reduce worker exposure to fumes.

- Assembly: Large gantry robots move and position heavy ship blocks.

By Type

- Articulated Robots: Flexible arms used for complex tasks.

- Collaborative Robots (Cobots): Designed to work safely alongside humans.

- Mobile Robots: Autonomous vehicles that move materials around the yard.

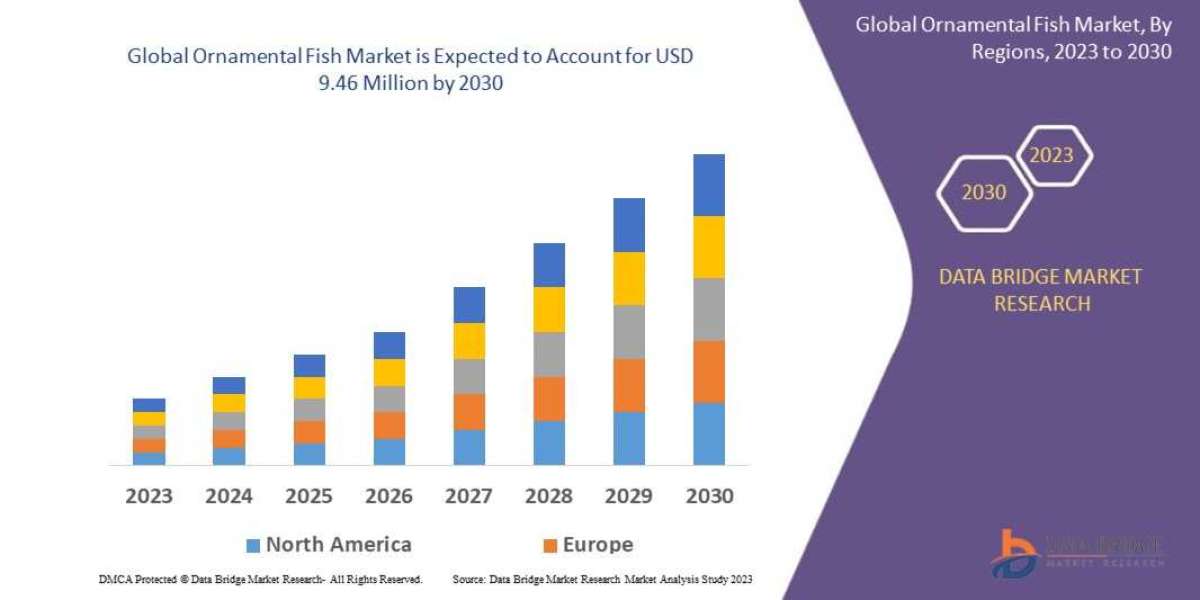

Regional Analysis

Adoption rates of robotics vary globally.

- Asia-Pacific: South Korea and Japan are leaders in robotic shipbuilding. They use massive automated systems to dominate the commercial market. Their investment in smart shipbuilding technologies is unmatched.

- Europe: European yards focus on specialized robotics for cruise ships and yachts. They use AI-powered ship design to create intricate interiors and complex hull forms.

- North America: The focus is often on retrofitting existing yards with robotic cells. This allows them to compete without building entirely new facilities.

Future Growth

The future of the digital shipyard market lies in autonomous collaboration. We will see robots that can communicate with each other to solve problems. If one robot falls behind, others will adjust their speed. This creates a fluid, self-correcting production line.

Virtual reality in shipbuilding will be used to program these robots. Operators will guide a robot arm in VR, and the physical robot will learn the movement. This makes programming complex tasks much easier.

Moreover, predictive maintenance in shipyards extends to the robots themselves. The system will ensure that the automated workforce is always healthy. Sustainable shipyard operations will also benefit. Robots use materials more efficiently, generating less scrap waste.

FAQs

- Will robots replace all human workers in shipyards?

No. Robots handle repetitive and dangerous tasks. Humans are still needed for complex decision-making and supervision.

- What is AI-powered ship design?

It uses algorithms to generate and test ship designs. AI can explore thousands of variations to find the most efficient one.

- Are robots used for maintenance?

Yes. There are robots designed to clean hulls and inspect tanks on existing ships.

- How does automation affect the cost of ships?

It requires high upfront investment but lowers production costs over time. This can eventually lead to more competitive ship prices.

- What is the role of Cobots?

Cobots assist workers with heavy lifting or holding parts in place. They act as a "third hand" for the human worker.

Conclusion

In conclusion, robotics and AI are transforming the digital shipyard market. They offer solutions to labor shortages and quality issues. By integrating shipyard automation solutions, builders can deliver better vessels faster. As AI-powered ship design evolves, the ships of the future will be born from a perfect marriage of human creativity and machine precision. This is the new era of shipbuilding.