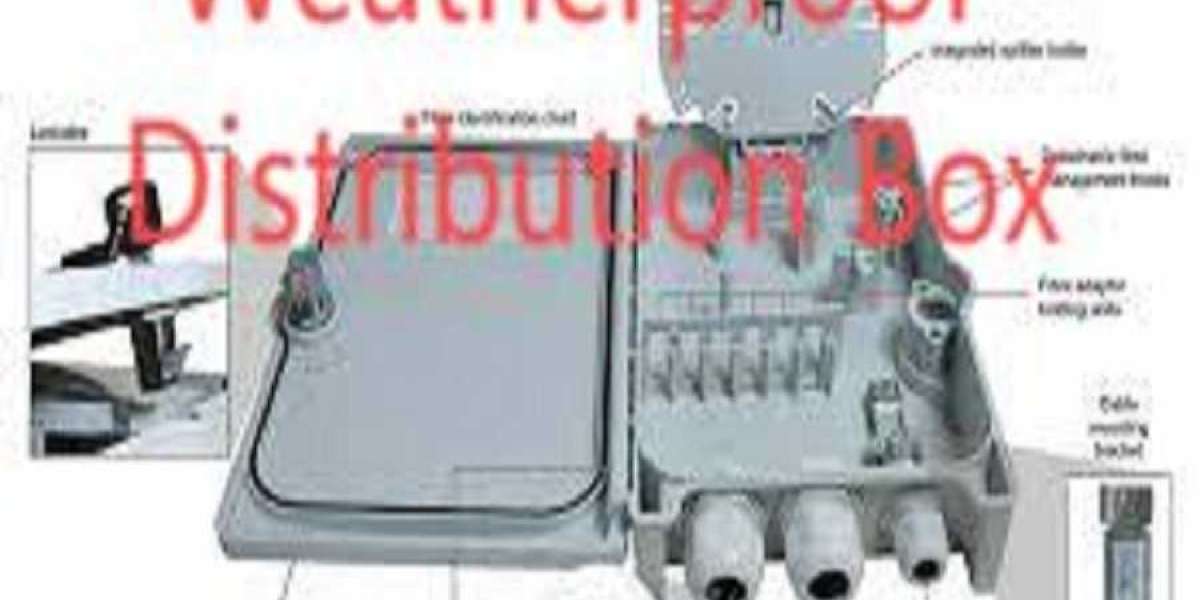

Outdoor power distribution demands enclosures that protect electrical systems from the elements without sacrificing accessibility, and a properly chosen Weatherproof Distribution Box provides both robust protection and practical serviceability in exposed installations. In project planning, engineers often specify a Weatherproof Distribution Box early so wiring, protection, and maintenance access can be coordinated — doing so reduces retrofit cost and prevents common field failures caused by moisture, dust, or thermal stress.

Materials and Corrosion Resistance

Material selection is the first determinant of long-term performance. For coastal or chemically aggressive sites, stainless steel or corrosion-grade alloys are preferred for frames and hardware; for general outdoor applications, powder-coated aluminum balances strength and cost. High-performance thermoplastics offer UV stability and impact resistance where weight is a concern. Equally important are stainless fasteners and coated hinges: mismatched metals can cause galvanic corrosion that quickly degrades seals and joints. Consider sacrificial coatings or anodizing for added protection in harsh atmospheres.

Sealing Geometry and Ingress Protection

A gasket is only as good as the door geometry that compresses it. Tongue-and-groove profiles with controlled compression grooves ensure repeatable sealing after many service cycles, while captive screws and torque-limiting washers promote consistent gasket compression in the field. For washdown and outdoor installations, target an IP66 or IP67 baseline and verify that all accessories — gland plates, conduit entries, and hoods — are included in the rated configuration. Pressure-equalizing vents with hydrophobic membranes prevent internal condensation without allowing liquid ingress, which is essential when enclosures experience rapid temperature changes.

Internal Layout, Cable Management, and Modularity

A well-organized interior saves installation time and simplifies future upgrades. Removable mounting plates, DIN rails, and snap-fit sub-panels let technicians pre-assemble modules off-site and perform rapid on-site swaps. Integrated cable channels and multiple strain-relief positions protect terminations from mechanical stress and extend component life. Modular breaker or fuse carriers let teams add circuits or replace parts without disturbing adjacent equipment, reducing energized exposure and improving safety during maintenance.

Thermal Control and High-Load Strategies

Heat accumulation shortens component life and increases nuisance trips. Passive measures — reflective exterior finishes, shaded mounting locations, and internal heat-spreading plates — reduce solar gain without adding moving parts. For densely populated enclosures or continuous high loads, filtered forced ventilation or compact heat exchangers keep internal temperatures within manufacturer derating curves. Layout matters: position high-loss components where airflow targets them first, and avoid crowding sensitive electronics near doors that receive direct sunlight.

Mounting, Security, and Site Adaptation

Choose mounting systems that match site constraints: pole kits and pedestals suit remote lighting and utility nodes, while surface-mount frames simplify retrofits. Use non-conductive spacers when attaching to dissimilar metals to prevent galvanic corrosion. For unattended locations, include tamper-resistant hardware, padlockable doors, and keyed access to deter vandalism. Design for post-storm recovery by including removable covers and positive drainage bosses so crews can perform quick temporary repairs and restore service rapidly.

Diagnostics, Maintenance Routines, and Spares Strategy

Make routine inspection painless: tool-free panels, captive screws, and clearly labeled terminals speed checks and reduce errors. Integrate basic diagnostics where useful — temperature sensors at critical terminations, fused-channel current monitoring, and humidity detectors — to provide early warnings before failures occur. Establish preventive schedules for gasket compression checks, terminal torque verification, and thermal imaging during planned outages. Maintain a compact local spares kit (gaskets, dust caps, common fuses) to shorten mean time to repair and keep systems running.

Retrofit Best Practices and Lifecycle Planning

When upgrading legacy sites, select enclosures that accept existing conduit patterns or offer adapter plates to avoid invasive wall work. Always verify and, if necessary, upgrade grounding and bonding — a new enclosure cannot compensate for poor earthing. Phased upgrades (installing basic protection first, then adding monitoring or metering later) spread capital costs while immediately improving environmental protection and serviceability.

Procurement Tips and Specification Checklist

Don’t evaluate enclosures on price alone. Factor in accessory availability, spare-part lead times, installation labor, and expected maintenance intervals. Request production samples or dry-fit kits, confirm proofing timelines for custom colors or finishes, and insist on clear accessory and spare-part catalogs from suppliers to avoid surprises during commissioning.

A thoughtfully specified outdoor distribution solution reduces unplanned outages, simplifies field service, and minimizes lifecycle cost. For technical specifications, accessory options, and ordering information, visit https://www.nante.com/news/industry-news/weatherproof-distribution-boxes-features-applications-future-trends-and-more.html