As Per Market Research Future, advancements in electromagnetic flow control valves are significantly impacting the solenoid valve market. These valves are designed to provide precise control over fluid flow, making them essential in various applications, including water treatment and chemical processing. The integration of smart technologies in electromagnetic flow control valves enhances their functionality, allowing for real-time monitoring and control. As industries increasingly adopt automation, the demand for advanced flow control solutions is expected to grow, driving further innovations in solenoid valve technology.

The Solenoid Valve Market has emerged as a cornerstone of industrial automation and fluid control systems. Solenoid valves are electromechanical devices that regulate the flow of liquids or gases in various applications, offering precise control, rapid response, and reliable operation. They are widely used across industries such as automotive, chemical processing, water treatment, HVAC, and pharmaceuticals. Their ability to operate remotely and automate complex processes has made them essential for improving productivity, safety, and energy efficiency.

Market Dynamics

The market growth of solenoid valves is driven by increasing automation across manufacturing, processing, and utility sectors. Modern industrial facilities prioritize efficiency and operational precision, creating a demand for reliable fluid control devices. Additionally, the automotive industry relies on solenoid valves for engine management, fuel injection systems, and emission control, further boosting market growth. The rise in smart infrastructure and automation technologies in buildings has also led to increased deployment of solenoid valves in HVAC systems, plumbing, and fire suppression mechanisms.

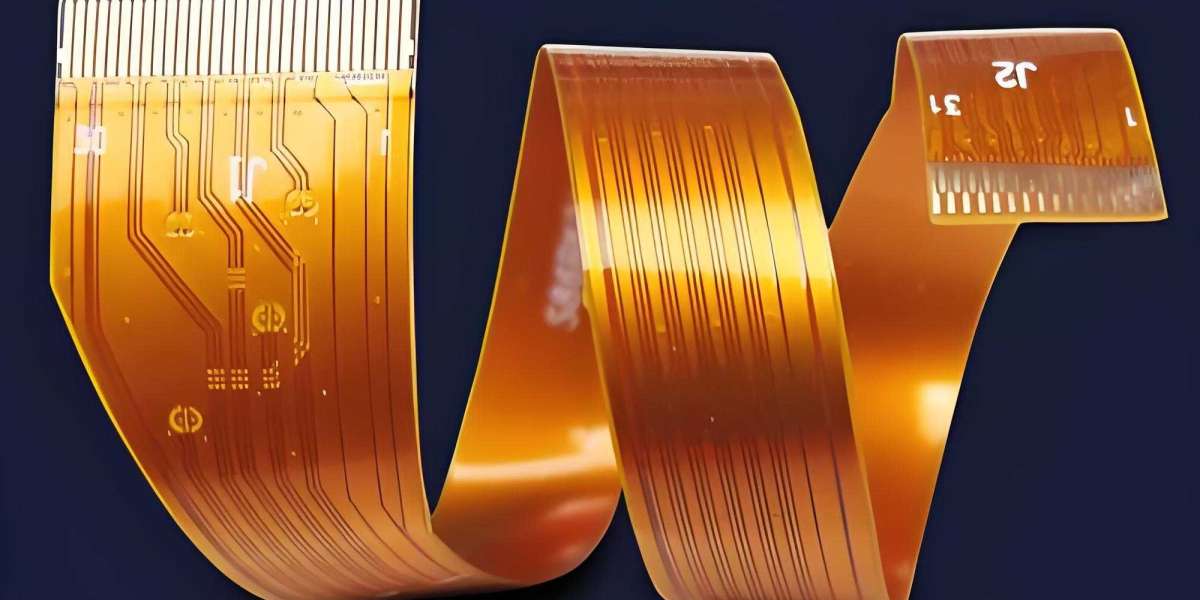

Technological innovation plays a crucial role in the market. Solenoid valves are being designed for high durability, corrosion resistance, and energy efficiency. Compact and lightweight designs allow integration into confined spaces without compromising performance. Advanced materials such as stainless steel, brass, and engineering plastics enhance longevity and chemical compatibility, expanding their applicability in harsh industrial environments. IoT-enabled solenoid valves capable of remote monitoring and predictive maintenance are transforming the industry by reducing downtime and improving operational efficiency.

Segmentation Analysis

Solenoid valves can be segmented by type, operation, application, and end-user. By type, they include direct-acting, pilot-operated, two-way, three-way, and four-way valves. Direct-acting valves operate independently of system pressure and are ideal for low-flow applications, while pilot-operated valves suit high-flow industrial processes. Two-way and three-way valves are commonly used in fluid routing, mixing, and isolation tasks.

Operation segmentation includes normally open, normally closed, and universal solenoid valves. Normally closed valves remain closed when de-energized, providing safety and preventing fluid leakage, whereas normally open valves allow continuous flow unless activated. Universal valves offer flexibility for varied operational requirements.

Applications include water treatment, chemical processing, automotive systems, HVAC, food and beverage processing, and pharmaceuticals. Water treatment plants utilize solenoid valves for precise flow control and automated operations. In chemical and pharmaceutical industries, they manage aggressive fluids safely. HVAC and automotive applications rely on solenoid valves for efficient system performance and regulatory compliance.

Regional Insights

The Solenoid Valve Market is distributed across North America, Europe, Asia-Pacific, Latin America, and the Middle East Africa. Asia-Pacific leads the global market due to rapid industrialization, growing automotive manufacturing, and increasing adoption of automation technologies. North America and Europe show steady growth driven by stringent regulations, technological advancements, and high adoption of smart building systems. Latin America and the Middle East Africa are witnessing gradual expansion, fueled by infrastructure development and industrial modernization projects.

Challenges and Opportunities

Despite the market's expansion, challenges remain. High costs of advanced solenoid valve systems may limit adoption among small-scale industries. Additionally, the need for skilled personnel to operate and maintain complex systems poses a barrier. However, opportunities exist in the form of smart solenoid valves, energy-efficient designs, and miniaturization for compact applications. Growing emphasis on sustainable and automated industrial processes presents a promising growth landscape.

Manufacturers focusing on RD for advanced materials, IoT integration, and energy optimization are likely to gain a competitive advantage. Partnerships with industrial automation and smart infrastructure providers offer opportunities to expand market reach and enhance product adoption.

Conclusion

The Solenoid Valve Market is set for substantial growth, driven by automation, technological innovation, and increasing demand across diverse industries. Its applications span from precision fluid control to energy-efficient industrial processes, positioning solenoid valves as indispensable components in modern operations. Companies investing in innovation, smart integration, and global expansion are expected to lead the market in the upcoming years.

FAQs

Q1: What industries use solenoid valves most?

A1: Automotive, chemical processing, water treatment, HVAC, and pharmaceuticals are primary users.

Q2: What are the main types of solenoid valves?

A2: Direct-acting, pilot-operated, two-way, three-way, and four-way valves are key types.

Q3: How are solenoid valves improving industrial efficiency?

A3: They enable automation, precise fluid control, remote operation, and energy savings.

More Related Reports:

Industrial Floor Scrubber Market Growth